Browse Tough Terrain: Why Selecting the Right Undercarriage Parts Matters

Browse Tough Terrain: Why Selecting the Right Undercarriage Parts Matters

Blog Article

Important Guide to Undercarriage Parts for Heavy Equipment

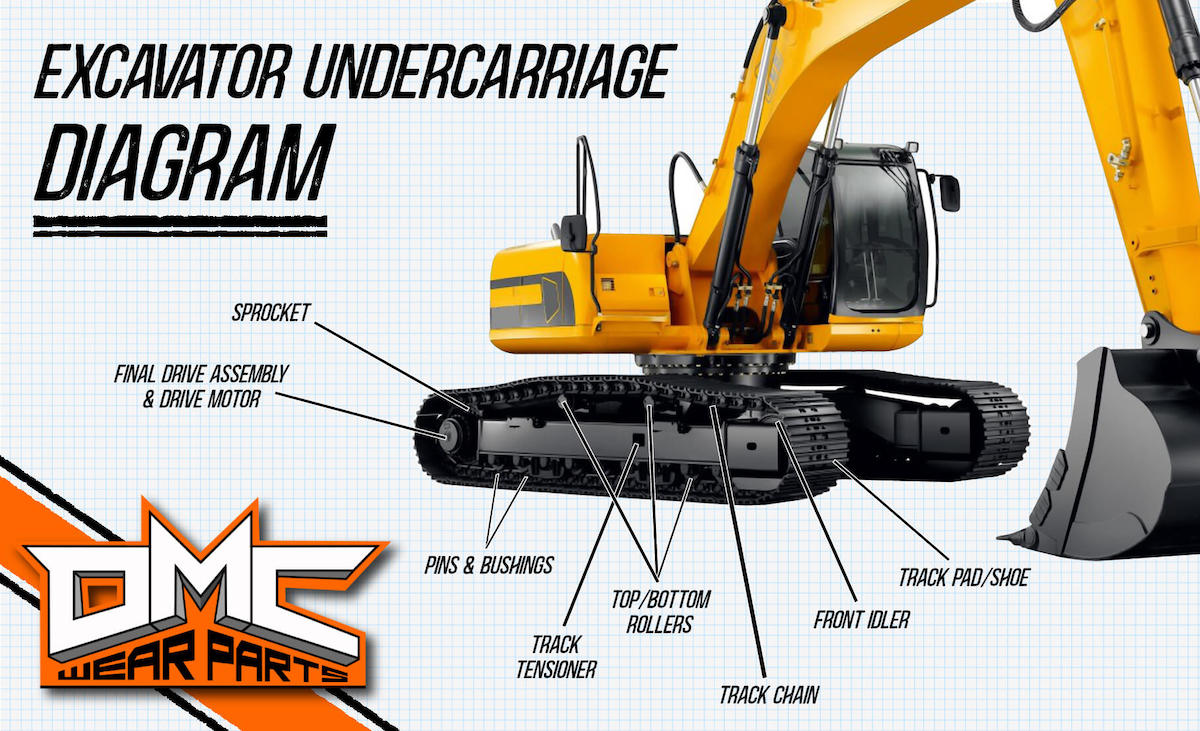

When it comes to heavy equipment, the undercarriage plays an essential role in making sure effective and smooth operations. From track chains to idlers and rollers, each component adds to the total performance of the tools.

Importance of Undercarriage Components

Understanding the critical function that undercarriage parts play in the performance and longevity of heavy devices is critical for efficient upkeep and operation - undercarriage parts. The undercarriage components form the structure on which the entire equipment runs, sustaining the weight of the devices, offering security, and soaking up shock lots throughout procedure. A well-maintained undercarriage not just makes sure smooth procedure however additionally adds substantially to minimizing downtime and repair service prices

The undercarriage is composed of different vital components such as track chains, track footwear, sprockets, idlers, rollers, and track frames. The track chains and track shoes aid in supplying grip and support, while the sprockets and idlers help in driving the tracks smoothly.

Sorts Of Track Chains

Track chains are necessary elements of heavy devices undercarriages, giving the essential grip and support for effective operation. There are primarily 2 kinds of track chains utilized in heavy tools: secured and oiled track chains (SALT) and dry track chains.

Function of Rollers and Idlers

Rollers and idlers play an important function in sustaining and assisting the track chains of heavy devices undercarriages, contributing to the total stability and efficiency of the machinery. Rollers are designed to sustain the weight of the equipment and provide a smooth surface for the track chain to relocate along. They help disperse the weight uniformly, minimizing too much wear on the track chain and making certain proper traction. Idlers, on the other hand, overview the track chain and assistance preserve proper stress throughout the undercarriage system. By assisting the track chain in a regulated way, idlers prevent too much side-to-side activity, minimizing the threat of derailment and uneven wear.

Together, idlers and rollers work in harmony to guarantee that the track chain stays in location, also on harsh surface, enhancing the tools's efficiency and longevity. Correct maintenance and routine evaluation of rollers and idlers are important to avoid early wear and potential break downs, ultimately optimizing the efficiency and life-span of hefty equipment undercarriages.

Recognizing Gears

One essential element of gears is making certain correct positioning and stress to avoid premature wear and damages. Misaligned gears can cause irregular endure the track chain, leading to lowered performance and possible security threats. Routine upkeep and assessment of gears are important to determine any type of signs of wear or misalignment promptly.

Furthermore, sprockets can be found in numerous dimensions and tooth configurations, depending on the certain heavy equipment and its desired use. Correct option of sprockets based upon the equipment's specifications is essential to make certain optimal performance and long life of the undercarriage system. Understanding the duty of sprockets and visit this site right here their upkeep demands is crucial for taking full advantage of the effectiveness and lifespan of hefty equipment undercarriages.

Maintenance Tips for Durability

To make certain the prolonged longevity and ideal performance of heavy tools undercarriages, attentive maintenance techniques are essential. Consistently inspecting undercarriage parts such as track footwear, rollers, idlers, and sprockets for wear and tear is vital. Proper track tension change is likewise crucial for minimizing early wear on undercarriage components.

Conclusion

In final thought, undercarriage parts are crucial parts for hefty tools, playing vital duties in preserving security and functionality. Appropriate treatment and attention to undercarriage components are key to taking full advantage of devices life expectancy and performance.

The undercarriage consists of various essential components such as track chains, track footwear, sprockets, idlers, rollers, and track frameworks. The track chains and track footwear help in offering traction and support, while the idlers and sprockets assist in driving the tracks efficiently (undercarriage parts). There are primarily two kinds Learn More of track chains utilized in hefty devices: secured and oiled track chains (SALT) and completely dry track chains. Proper choice and upkeep of track chains are essential to make sure the general performance and longevity of heavy tools undercarriages

Sprockets are indispensable parts of hefty devices undercarriages, responsible for moving power from the equipment to the track chain.

Report this page